Bangalore, famously known as the City of Entrepreneurs, is home to some of the most brilliant minds of the century. Here, people are driven by a relentless work ethic, pushing boundaries and striving for excellence. But it's not all work and no play. The proud founder of iWort, meet Mr. Ankur Napa, a Bangalore-based brew-master whose love for beer and AI has turned him into a data scientist in the beer world.

Personal Background

Could you share your journey from starting in the brewing industry to becoming a Product Owner at iWort?

My journey in the brewing industry began with a deep-rooted passion for the craft. I pursued a Bachelor of Technology in Biotechnology from UIET, MDU, which laid the foundation for my scientific approach to brewing. My early experiences at Hops & Grains the Microbrewery fueled my passion, leading me to earn a Master of Science in Wine, Brewing & Alcohol Technology from Savitribai Phule Pune University. This education, combined with hands-on experience, opened doors to prominent roles at ABInBev and SABMiller, where I honed my skills in both craft and commercial brewing.

Transitioning to data science, I pursued a PG Diploma in Business Analytics from IIIT Bengaluru and a Master of Science in Data Science from Liverpool John Moore University. My analytical skills, coupled with brewing expertise, led to my role as a Senior Data Analyst at Mathesis Labs. I have worked with leading beer companies like ABInBev, United Breweries, and SABMiller. As the founder of iWort, I continue to drive advancements in brewing technology, helping breweries improve their processes, develop new recipes, and maximize sales.

You’ve mentioned the importance of svadhyaya (self-study) in brewing. How has it influenced your daily work?

Svadhyaya, or self-study, has been a cornerstone of my professional growth. In brewing, the science and techniques are ever-evolving, and continuous learning is essential. This philosophy has driven me to constantly seek knowledge, whether through academic pursuits, industry literature, or hands-on experimentation. In my daily work, svadhyaya manifests as a commitment to staying updated with the latest brewing technologies and data analytics methodologies. It ensures that I bring innovative solutions to the table, enhancing both the brewing processes and the analytical tools I develop.

You started brewing at a very young age. How did you manage the challenges and opportunities that came with starting early?

Starting my brewing career at a young age presented both challenges and opportunities. One of the primary challenges was gaining credibility and respect in an industry dominated by more experienced professionals. I tackled this by consistently delivering high-quality work and demonstrating a strong grasp of brewing science. The opportunities were plentiful, as starting early allowed me to accumulate a wealth of experience and knowledge over the years. It also meant I could be more adaptable and open to new technologies and methods, which has been invaluable in my transition to data science and my current role.

You have experience in both craft and commercial brewing. How do these two areas differ, and what do you enjoy most about each?

Craft and commercial brewing, while rooted in the same fundamental processes, differ significantly in scale, approach, and culture. Craft brewing emphasizes creativity, experimentation, and a personal touch. I enjoy the artistic and innovative aspects of craft brewing, where each batch can be a unique creation.

Commercial brewing, on the other hand, focuses on consistency, efficiency, and scalability. It involves stringent quality control measures and large-scale production techniques. What I appreciate most about commercial brewing is the challenge of maintaining high standards across vast quantities of beer and the opportunity to work with state-of-the-art equipment and processes.

In both areas, the blend of creativity in craft brewing and the precision required in commercial brewing has shaped my holistic understanding of the industry, enabling me to innovate and excel in my current role. These days, I am focused on making AI and data analytics affordable for both craft and commercial brewing, enabling breweries to strategically sell their beer at the right time and place to meet consumer demand more effectively.

Brewing Expertise

What drives your passion for brewing, and how do you integrate your knowledge of AI/ML in the brewing process?

My passion for brewing is driven by the perfect blend of science, creativity, and tradition it embodies. The process of transforming raw ingredients into a delightful beverage is both an art and a science, which fascinates me.

Integrating AI and machine learning into the brewing process allows me to harness data to improve consistency, efficiency, and innovation. By analyzing vast amounts of data from various brewing stages, AI can identify patterns and optimize processes. For instance, machine learning algorithms can predict the optimal fermentation conditions, reducing the risk of batch spoilage and improving yield. AI-driven predictive analytics can forecast demand, helping breweries adjust production schedules and inventory levels accordingly. Additionally, AI can assist in recipe development by analyzing consumer preferences and historical data, suggesting modifications to create beers that align with market trends.

[caption id="attachment_31538" align="aligncenter" width="1826"] Fermentation report from iWort Lab[/caption]

Fermentation report from iWort Lab[/caption]

What are the most significant changes you’ve observed in the brewing industry over the past decade?

Over the past decade, the brewing industry has undergone several significant changes:

Technological Advancements: The adoption of advanced technologies like AI, machine learning, and automation has revolutionized brewing. Automation of brewing systems and the use of data analytics for quality control and predictive maintenance have become more common.

Craft Beer Boom: There has been a remarkable rise in the popularity of craft beer. This trend has led to a proliferation of craft breweries, each offering a diverse range of styles and flavors.

Sustainability Initiatives: Efforts to reduce water usage, energy consumption, and waste have gained momentum. Breweries are adopting eco-friendly practices, such as using renewable energy sources, recycling water, and minimizing packaging waste.

Consumer Preferences: There has been a shift in consumer preferences towards healthier and more diverse beverage options. Low-alcohol, non-alcoholic, and gluten-free beers have gained popularity. Additionally, consumers are showing interest in innovative flavors and ingredients, driving experimentation and creativity in brewing.

Data-Driven Decision Making: From optimizing production processes to understanding consumer preferences, data-driven insights are helping breweries make informed decisions.

Regulatory Changes: The brewing industry has seen changes in regulations related to production, distribution, and labeling. These changes vary by region but have generally aimed at ensuring quality, safety, and transparency for consumers.

These changes have collectively contributed to a more dynamic, innovative, and consumer-centric brewing industry. As a professional in the field, it has been exciting to witness and contribute to these advancements, blending traditional brewing practices with modern technology to shape the future of brewing.

How Data Management Systems Elevates Craft Brewery Sales And Operations

Data Science and AI

Can you discuss specific ways you’ve used machine learning to improve brewing processes?

Certainly! My work with machine learning in brewing is rooted in my passion for blending traditional brewing expertise with modern data science and here’s how it shows as discussed in my article in Midday:

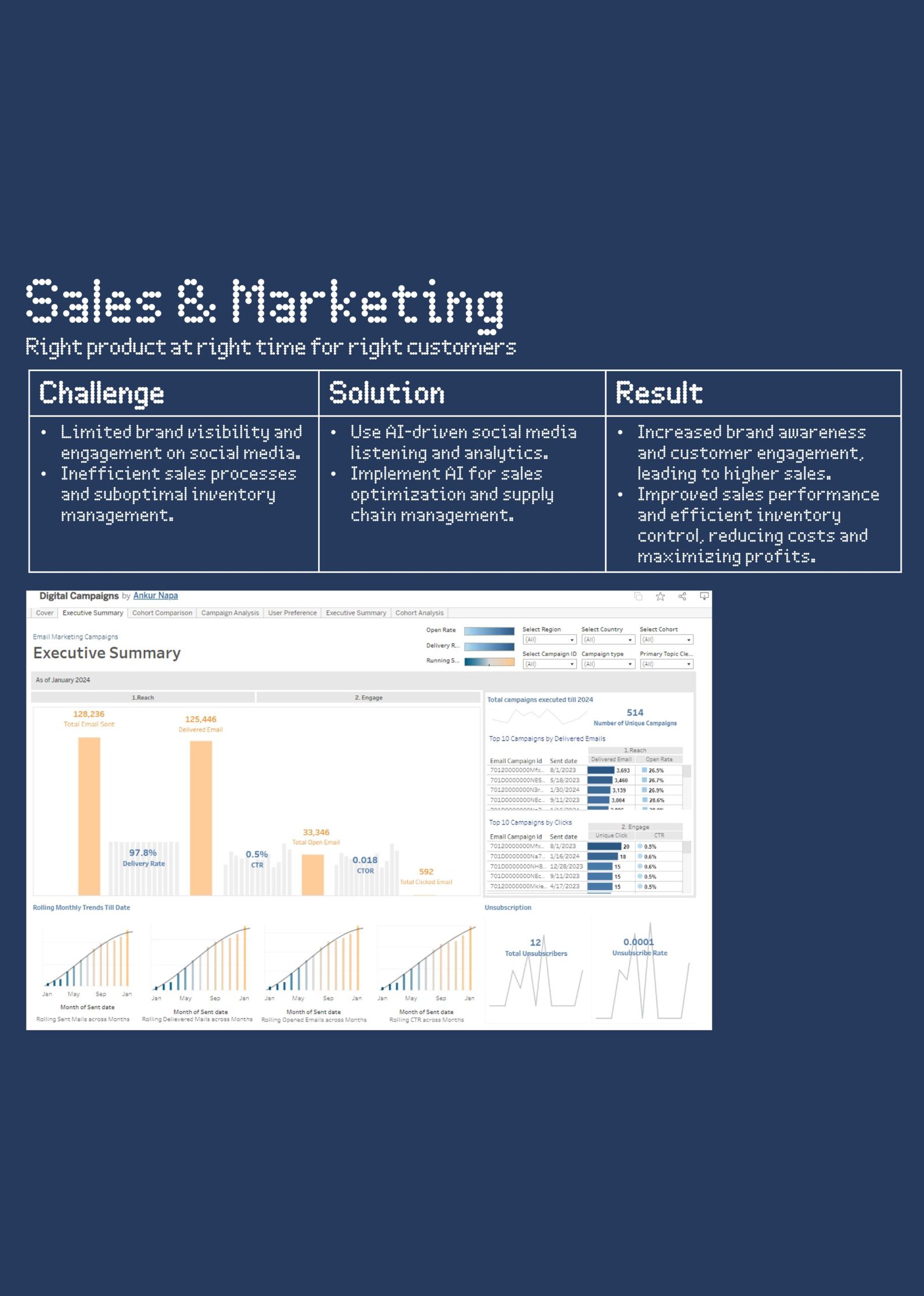

Consumer Palate Analysis: I have developed algorithms that analyze consumer reviews and feedback to detect shifts in beer preferences. By collecting data from various sources, including social media and direct consumer feedback, the machine learning models can identify trends and preferences. This real-time feedback loop helps in adjusting recipes quickly to meet changing tastes.

Recipe Optimization: Machine learning models analyze historical data on beer recipes and consumer reactions to optimize brewing formulas. By correlating ingredients, brewing methods, and consumer satisfaction, these models suggest the best combinations to achieve desired flavors and qualities. This approach not only improves product quality but also reduces trial and error in the development of new recipes.

Predictive Maintenance: Machine learning algorithms monitor brewing equipment and processes to predict potential failures or maintenance needs. By analyzing data from sensors and historical maintenance records, these models can forecast when equipment might need servicing, preventing downtime and ensuring smooth operations.

Yield Prediction and Inventory Management: Machine learning helps in predicting the yield of brewing batches based on various input parameters, such as ingredient quality and brewing conditions. Additionally, these models assist in inventory management by forecasting demand for different beer styles, ensuring that breweries produce the right quantities and minimize waste. This predictive capability is crucial for maintaining optimal stock levels and meeting consumer demand efficiently.

Market Trend Analysis: By analyzing market data and sales figures, machine learning models can identify emerging trends and preferences. This information helps breweries to adapt their product offerings and marketing strategies to align with consumer demand. For example, the algorithms can detect a rising preference for certain types of beer during specific seasons, guiding breweries to focus their production accordingly.

Operational Efficiency: Machine learning models optimize various operational aspects, such as fermentation times and temperatures, to enhance efficiency and consistency. By analyzing historical process data, these models provide insights into the optimal conditions for brewing, leading to more consistent product quality and reduced resource consumption.

These applications of machine learning in brewing not only enhance the quality and consistency of the beer but also streamline operations, reduce costs, and improve overall efficiency. By leveraging data-driven insights, I aim to bring innovation and excellence to the brewing industry.

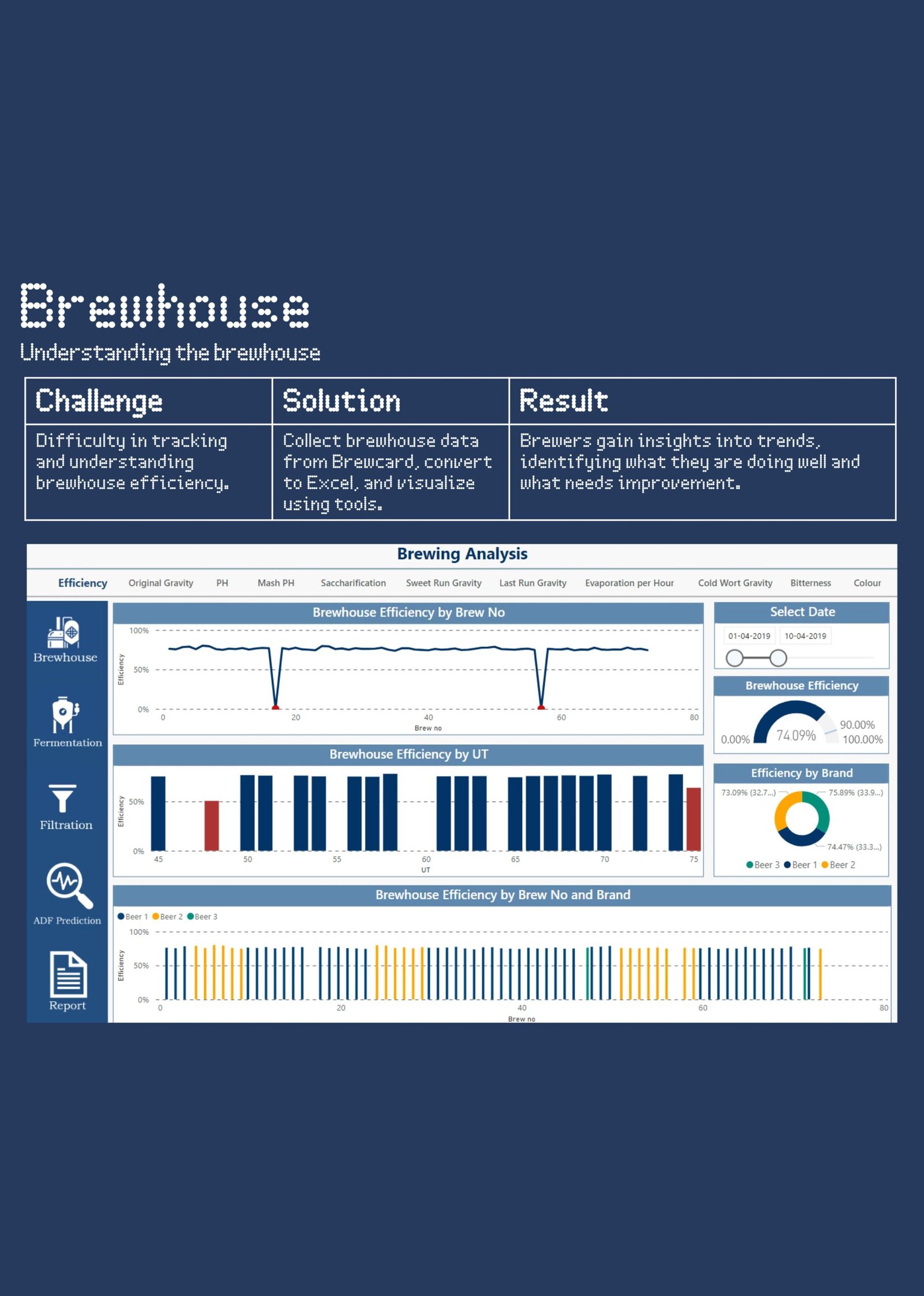

[caption id="attachment_31539" align="aligncenter" width="1826"] Brewhouse report from iWort Lab[/caption]

Brewhouse report from iWort Lab[/caption]

How do you utilize technology in your role at iwort, and what benefits does it bring to your projects?

At iWort, technology plays a pivotal role in driving innovation and optimizing brewing processes. Here are the ways I utilize technology and the benefits it brings to our projects:

Data Integration and Analysis: By leveraging advanced data analytics tools and platforms, such as Microsoft Power BI, SQL, and Python, I can integrate and analyze data from various sources. This comprehensive analysis helps in identifying trends, optimizing recipes, and improving overall efficiency. The ability to visualize data through interactive dashboards provides actionable insights that guide decision-making.

Machine Learning Models: Implementing machine learning algorithms allows us to predict consumer preferences, optimize brewing conditions, and enhance quality control. For example, our models analyze consumer feedback and market data to suggest recipe adjustments, ensuring that our beers meet the highest standards of taste and quality. Predictive maintenance models also help in forecasting equipment needs, minimizing downtime and ensuring smooth operations.

Automation and IoT: Utilizing IoT devices and automation technology, we monitor various parameters throughout the brewing process. Real-time data collection and automated adjustments ensure consistency and precision, reducing the margin for error and enhancing product quality. Automation also streamlines repetitive tasks, freeing up time for our team to focus on innovation and creative aspects of brewing.

Cloud Computing: Cloud platforms such as Azure and Google Cloud enable scalable data storage and processing capabilities. This scalability is crucial for handling large datasets and performing complex analyses efficiently. Cloud-based solutions also facilitate collaboration among team members, allowing for seamless sharing of data and insights.

AI-Driven Insights: AI-powered tools provide deep insights into market trends, consumer behavior, and operational efficiencies. By harnessing these insights, we can develop targeted marketing strategies, optimize inventory management, and improve supply chain logistics. This proactive approach ensures that we stay ahead of market demands and continuously deliver high-quality products.

Digital Twin Technology: Creating digital twins of our brewing processes allows us to simulate and optimize various scenarios. This virtual modeling helps in identifying potential improvements, testing new recipes, and refining processes without interrupting actual production. Digital twins provide a safe environment for experimentation and innovation.

The benefits of utilizing technology at iWort are manifold, including improved product quality, operational efficiency, and customer satisfaction. Technology enables us to make data-driven decisions, enhance our brewing capabilities, and maintain a competitive edge in the market.

How do iwort solutions contribute in brewing business benefits?

iWort's solutions enhance brewing operations using advanced technologies. Our AI and machine learning algorithms optimize fermentation and ingredient ratios, ensuring consistently high-quality beer, which boosts customer satisfaction and brand loyalty. Automation and IoT integration reduce human error and downtime, while predictive maintenance models forecast equipment failures for smoother operations and longer equipment lifespan.

Our data-driven recipe optimization analyzes consumer preferences and market trends, allowing breweries to create successful beer varieties quickly. Predictive analytics improve inventory and supply chain management by forecasting demand and optimizing production schedules, reducing overproduction and waste.

Comprehensive data analytics provide actionable insights into all brewing aspects, enhancing productivity and profitability. Sustainability is supported by optimizing resource usage, reducing water and energy consumption, and minimizing raw material waste. Market competitiveness is boosted as breweries adapt to changing dynamics based on consumer insights, helping develop targeted marketing strategies and capturing greater market share.

iWort's technology fosters continuous improvement, leading to new product development and refinement of existing processes. Overall, our solutions empower breweries to achieve high-quality production, operational efficiency, sustainability, and a strong market presence, effectively meeting consumer demand and driving business success.

[caption id="attachment_31540" align="aligncenter" width="1826"] Sales & Marketing report from iWort Lab[/caption]

Sales & Marketing report from iWort Lab[/caption]

Industry Insights

What are some challenges in the brewing industry that you are trying to fix using data?

Consistency in Quality: Using data to identify patterns and correlations that affect quality, ensuring optimal brewing conditions and consistent output.

Yield Optimization: Applying predictive analytics to forecast expected yield and fine-tune the brewing process to maximize efficiency and minimize losses.

Demand Forecasting: Analyzing historical sales data and market trends with machine learning to accurately forecast consumer demand and plan production schedules.

Inventory Management: Optimizing inventory levels by predicting usage patterns and lead times, reducing holding costs and minimizing stockouts.

Equipment Maintenance: Utilizing predictive maintenance models to analyze sensor data and forecast equipment failures, enabling proactive maintenance and reducing downtime.

Recipe Development: Leveraging consumer feedback and market trends to understand flavor preferences and develop innovative beer recipes that align with consumer tastes.

Operational Efficiency: Identifying bottlenecks and inefficiencies through data analytics to optimize workflows, enhance productivity, and reduce operational costs.

Sustainability: Monitoring and analyzing resource usage to optimize consumption, reduce waste, and enhance sustainability practices in brewing operations.

Customer Engagement: Analyzing customer data to understand preferences and purchase behavior, enabling personalized marketing campaigns and targeted promotions to build loyalty.

[caption id="attachment_31541" align="aligncenter" width="1826"] Summary of good selling beers from iWort Lab[/caption]

Summary of good selling beers from iWort Lab[/caption]

You mentioned the impact of younger generations entering the brewing industry. How do you think this will shape the future of brewing?

The influx of younger generations into the brewing industry is set to shape its future in several significant ways:

Innovation and Creativity: Younger brewers bring fresh perspectives and a willingness to experiment with new flavors, ingredients, and brewing techniques. Their creativity is likely to lead to innovative beer styles and unique offerings that appeal to a broader audience.

Technology Adoption: Growing up in the digital age, younger brewers are more comfortable with technology and data analytics. Their proficiency with digital tools will drive the adoption of advanced technologies in brewing, enhancing efficiency, quality, and sustainability.

Diverse Preferences: Younger generations have diverse tastes and preferences, often favoring artisanal and authentic products. This will push breweries to diversify their portfolios and cater to a wider range of consumer tastes, including niche and specialty beers.

Sustainability Focus: Environmental consciousness is strong among younger generations. They are likely to prioritize sustainable brewing practices and champion initiatives that reduce the environmental impact of brewing, from sourcing ingredients to packaging and distribution.

Community Engagement: Younger brewers value community and social connections. They are likely to foster stronger community ties through local collaborations, events, and social initiatives, creating a more engaged and loyal customer base.

Inclusive Work Culture: As younger generations enter the industry, there will be a push for more inclusive and diverse work environments. This cultural shift will not only benefit the workforce but also influence the industry’s overall approach to marketing and customer engagement.